I decided that I would make up a couple of nucleus hives to supplement the two I already have. I find it easier to carry out swarm control and queen rearing with nucs rather than having to use full size hives

I have gone for what is the most common nuc size – 5 frames. This way there’s room for expansion and it’s the right size when fully occupied to be transferable to a full size hive without worrying if the bees can keep the cluster warm enough in a bigger brood box.

The plans are available as a pdf download -see link at the end of the post.

As I have access to Western Red Cedar I made the boxes from this and treated then with two coats of boiled linseed oil to give them a bit of protection. You can also use pine or even plywood, ideally marine.

Design Considerations

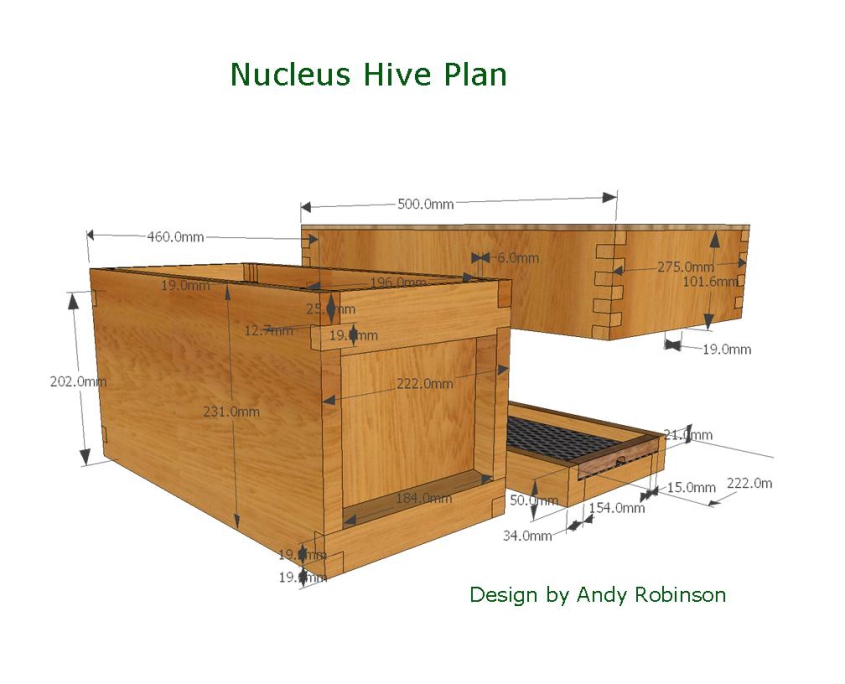

The floor is separate from the nuc body and is retained in place by two spring clips. In the past I have gone for solid wood floors but put in mesh ones this time around as it’s helps with Varroa management. Rather than having a deep roof I tend to use an eke to accommodate a feeder when required. The 101mm depth makes it easier to cut the box joint to a whole number of 12.7mm cuts.

I was faced with two restrictions with my dimensions:

- The roof metal was 500x275mm and in hindsight I should have used slightly thinner wood for the roof sides to make it a looser fit – probably 15mm rather than the 19mm shown in the plan.

- The overall inside length to accommodate the lugs of National frames needs to be around 436mm across the top.

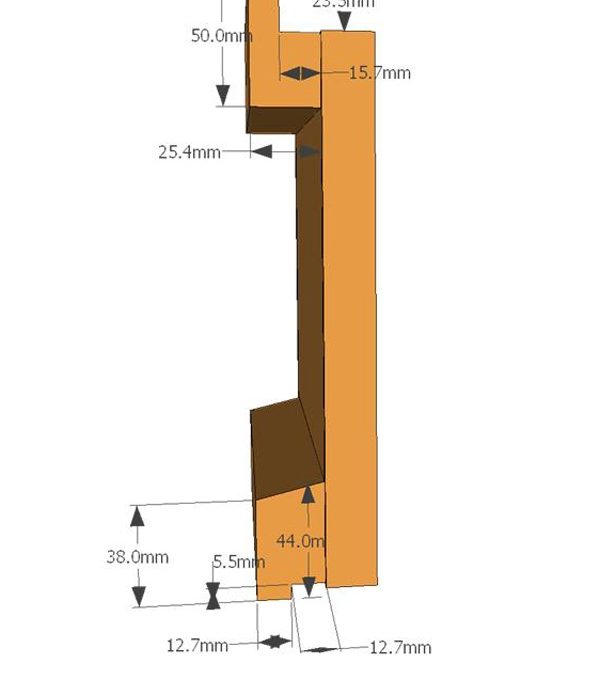

The joints and rebates are the same as those on a standard hive (see section view image for details). I kept the overall length the same as a standard brood body at 460mm so that I can perform a unite with a full size hive if required. If you can’t get the right thickness timber for the floor runners then consider gluing two pieces together to give the correct dimensions. Not included in the plan are the entrance block and cover-board which are fairly easy to make up. I have also fixed battens in the roof to make sure I don’t squash any bees when putting the roof on.

Assembly

I use a table saw to cut the cedar timber to size, as per the cutting list in the pdf (see link below). For the tenons, side rebates and roof box joints I use a router. Cut the ventilation slots in the end boards – either use a saw and a chisel or if you know what you are doing a router can be used

Then it’s just a case of assembling the parts

- Glue up the floor, nuc body and roof with wood glue – I use Titebond II. Check for square and clamp up.

- Nuc body – use 30mm nails to strengthen support for the key areas:

- Top and bottom fillet tenons into ends of nuc sides – 8 in total

- Sides where the front and back ends of the body slot into the shallow rebates – 2 per rebate -8 in total

- Floor- fix at each corner with 40mm screws. Pre-drill with pilot holes to prevent splitting. Secure the mesh floor on top of the rebates on the long runners and the top of the front and back supports with 10mm staples

- Roof – use 30mm nails to strengthen the box joint at the lower corners

- Fix some gauze or mesh on the inside to prevent the bees from trying to use it as an exit/entrance.

- Use panel pins to fix the ply cover to make the top of roof.

- Fit battens to inside of roof.

- Fix metal cover to roof once any finish, such as linseed oil has been applied

Finishing

Sanding all pieces prior to assembly makes it easier than trying to do it once glued up. Cedar is durable and doesn’t need any finishing but I like to apply 2 coats of boiled linseed oil. This gives the hive a bit more protection and makes the surface of the wood a bit more resistant to denting.

![]() Click the link to open Invalid download ID. Size: Invalid download ID.

Click the link to open Invalid download ID. Size: Invalid download ID.